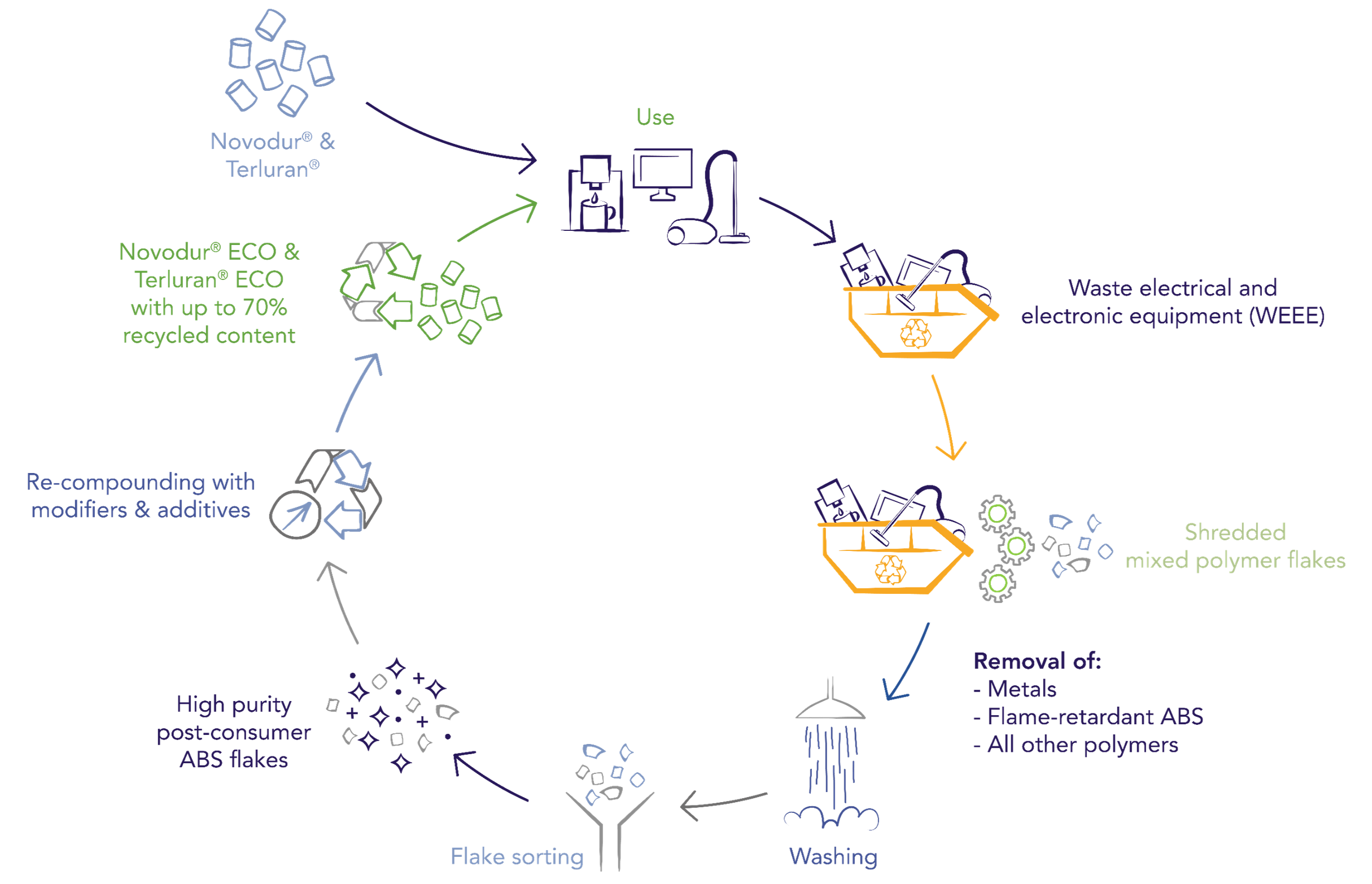

ABS is a styrenics material that, due to its light weight, helps conserve energy and reduces fuel consumption in the automotive industry, reduces energy consumption, and protects electronic equipment and household appliances with aesthetic and durable housings. Moreover, ABS is also entirely recyclable.

To make sure this valuable material is not wasted and disposed after one use, we have optimised a process called mechanical recycling. This is a method by which industrial or post-consumer waste is physically processed back into pellets, without changing the basic chemical structure of the material.

Mechanical recycling: a proven technology that works for various styrenics polymers

Terluran® ECO, Novodur® ECO and Novodur® ECO HH, our recycled ABS grades are made with post-consumer recycled WEEE (waste electrical and electronic equipment), which mainly comprise household appliances and tools, televisions, and computers that have reached the end of their life. What is trendsetting about these products is that it offers premium quality and high performance. So, no downcycling needed.