Press Release, 06/01/22, Shanghai, China

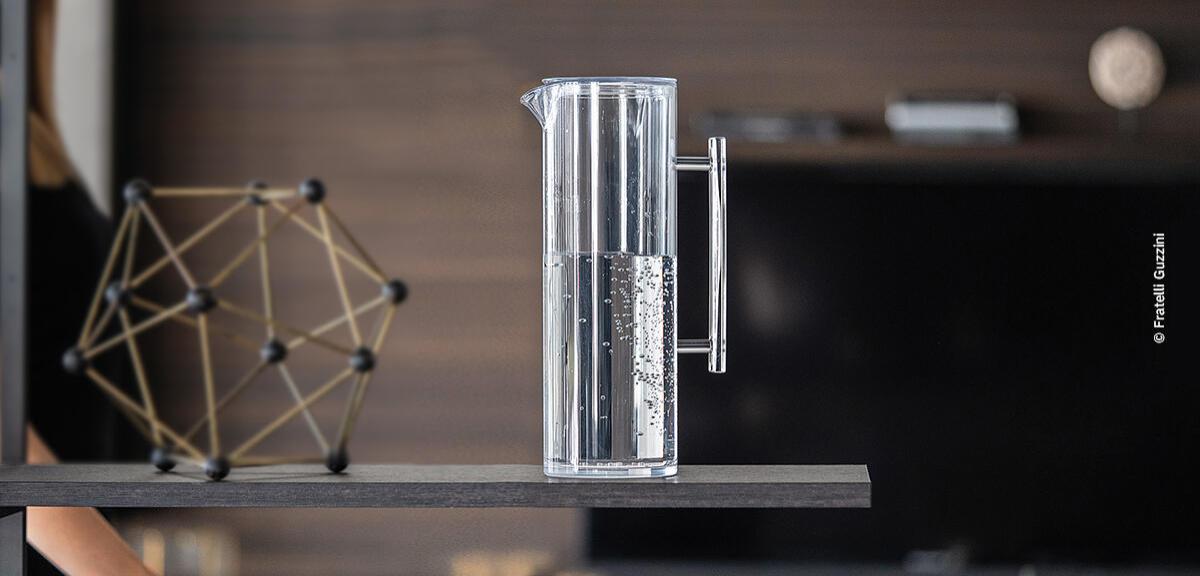

- New Guzzini drinkware made from INEOS Styrolution’s sustainable ECO materials

- BASF to supply biomass balanced styrene as plastic feedstock

- Completely certified production process

Fratelli Guzzini has today announced it has selected a range of INEOS Styrolution’s sustainable NAS® ECO materials as materials of choice for its new range of drinkware solutions. NAS ECO is a styrene methyl methacrylate (SMMA) material, which is the result of a cooperation between INEOS Styrolution and BASF. It is built on BASF’s production of styrene monomer derived from renewable feedstock based on mass balance based processes. INEOS Styrolution uses the material as feedstock in its production of new sustainable styrenics solutions.

First customer in tableware and household appliances to benefit from the new solutions is Fratelli Guzzini, a world leading company in this sector.

Domenico Guzzini, President at Fratelli Guzzini, comments: “We are pleased to respond to the growing demand from our customers to deliver solutions with a significantly reduced impact on the environment.”

NAS ECO with significantly reduced CO2 footprint

BASF’s biomass balance (BMB) based styrene is used by INEOS Styrolution in the production of bio-attributed styrenics specialties, mainly transparent styrenics materials such as the company’s NAS® family of SMMA (styrene methyl methacrylate) products and the Luran® family of SAN (styrene acrylonitrile copolymer) products.

The end-to-end mass balanced based production of the new solution portfolio is certified by ISCC during BASF’s and INEOS Styrolution’s processes.

Mark Beitz, Head of Sustainability, R&D and Regulatory, at INEOS Styrolution comments: “The joint approach with BASF allows us to offer our customers solutions with a significantly reduced CO2 footprint that help them to deliver sustainable solutions to end users.”

(Bio)mass balanced styrene

To produce BMB styrene, BASF replaces fossil resources like naphtha or natural gas by renewable feedstocks derived from organic waste or vegetable oils. It is one way to produce styrene via a mass balance approach. Mass balance is a chain of custody model that keeps track of the total amount of (e.g., circular or other alternative) feedstock throughout the production process and ensures a proper allocation to the finished goods.

Raw material and plastic producers like INEOS Styrolution and BASF can thus offer products with a better environmental profile but the same properties as those manufactured from fossil feedstock. The allocation process via the mass balance approach as well as the products are certified by independent auditors. Read more about BASF’s Biomass Balance Biomass balance approach (basf.com). “Using biomass-balanced based (BMB) feedstocks instead of virgin fossil resources contributes directly to an improved CO2 footprint of subsequent products,” says Klaus Ries, Vice President for BASF’s Styrenics Business Europe. “Next to raw materials based on chemically recycled feedstock, BMB is the second strong pillar for us when it comes to using alternative feedstock and contributing to the replacement of new fossil resources. It is of utmost importance for us to cooperate along the whole styrenics value chain.”

About GUZZINI

Guzzini, Creative Italian manufacturing, was established in 1912, based on the handcrafting of ox horn items, and has been a leading manufacturer of plastic designer items for the home for more than a hundred years. The top names in international design have chosen to work with Guzzini, appreciating its amazing ability to combine style and function. The Guzzini company history reveals impressive credentials in the areas of ethics, social responsibility and innovation so in 2019 it is launching the CIRCLE programme, to transition from the "material-production-use-waste" production chain to the circular "recovery-recycling-production-reuse-recovery" system. Circle comprises products made from eco-sustainable materials, with improved functional performances. Research into design and function, the trialling of constantly new materials, skilfully combined, the respect for the environment and the courage to be constantly innovative, make Guzzini one of the symbols of fine Italian manufacturing worldwide.

GUZZINI CONTACT

Gianni Romandini

Marketing Manager

Fratelli Guzzini spa us

C.da Mattonata, 60

62019 Recanati Mc

Italy

Email: gianni.romandini@fratelliguzzini.com

Website: www.fratelliguzzini.com

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. Around 111.000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio comprises six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €78.6 billion in 2021. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com.

BASF MEDIA CONTACT

Dr. Sabine Philipp

Head of Industry Affairs & Public Relations Styrenics EU

sabine.philipp [@] basf.com

Phone: +49 621 60 43348