Let’s take a closer look at what it takes to get ECO products made from renewable feedstock from an idea to a commercial solution.

We want to grow our ECO portfolio while maintaining our high product performance and supporting the transition to a low-carbon, circular economy. A key driver for our business, and the chemical industry as a whole, is the mass balance concept, that we also refer to as bio-attribution.

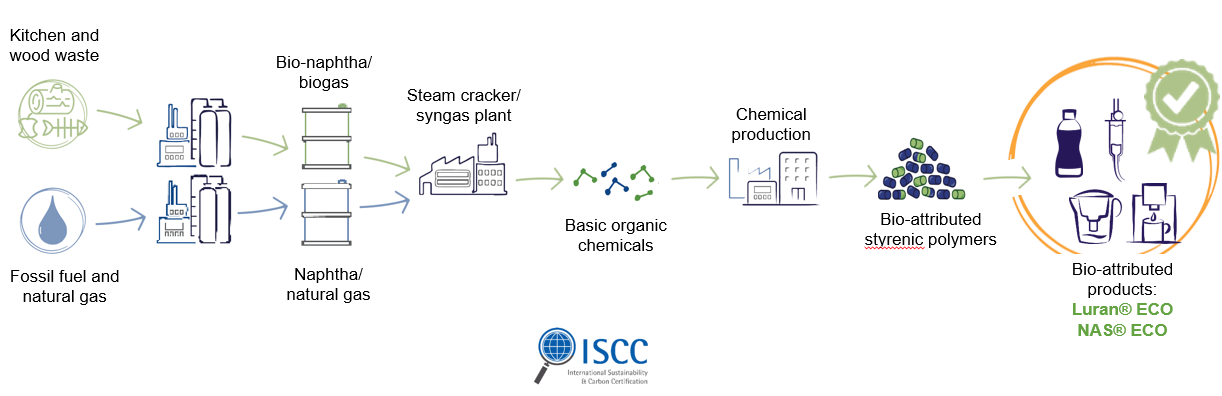

Mass Balance is a chain of custody concept that allows mixing of renewable (or recycled) and fossil raw materials with a robust book-keeping process in place to prevent over-claiming of sustainable shares. Mass balance enables a seamless and efficient transition to incorporating recycled or renewable feedstock along with fossil-based feedstock in existing large-scale assets and can be integrated in complex supply chains. Mass balance methodology is therefore necessary to ensure accurate calculation and verification of the amount of recycled or renewable content allocated to products.

MASS BALANCE. CERTIFIED.

INEOS Styrolution’s mass balance concept has been certified under the International Sustainability and Carbon Certification (ISCC), which is the global leading certification system for mass balance. As of today, seven production sites including warehouses in Antwerp, Altamira, Channahon, Cologne, Ludwigshafen, Schwarzheide, and Texas City have been certified and we also have a global ISCC PLUS trader certification in place to allow cross-regional sales of our ECO products.

Three additional sites will undergo certification this year. Under ISCC, certified companies must follow the same rules to insure traceability throughout the supply chain, from the initial input of the sustainable feedstock until sale to the end-customer of the entire chain.

WHERE DOES IT BEGIN?

Multiple departments work together to get our bio-attributed ECO products to our customers. It begins with the business teams that select production sites offering high potential ECO products ranges by evaluating market outlooks and customer requests.

The ISCC PLUS mass balance certification is an important part of our overall commercial strategy to help our customers reach their sustainability goals. This is why we are taking a leadership role in driving verifiable, sustainable solutions that our customers can use to meet growing customer needs for a more sustainable future.

CLOSE COLLABORATION FROM START TO FINISH

Once a site has been registered under ISCC, the certification body sets an audit appointment, audit documents are prepared, trainings are executed with relevant colleagues from different departments. The auditor then visits our sites and evaluates our documentation, processes, inspects the installations and warehouses, and issues the ISCC certificate if all audit requirements are met. The audit is repeated annually to ensure that the sites remain certified.

Once a site has been certified, we purchase ISCC-certified feedstock, which is added to our on-site storage tanks. Our manufacturing processes are not affected by the use of renewable or recycled feedstock as they are co-processed along with conventional, fossil-based feedstock.

Each step of the sourcing and production process using this approach is certified under ISCC, meaning that the processing of the renewable feedstock along the entire supply chain from sourcing to distribution is socially responsible, environmentally sustainable, and credibly sourced.

MASS BALANCE: FROM IDEA TO COMMERCIALISATION

All our ECO products are based on our existing grades, and have their own material name and number. The manufactured goods are shipped to our customers, accompanied by an ISCC Sustainability Declaration ensuring the content of sustainable share.

Fair to say, the mass balance process has GEAR(ED) UP to let our ECO business grow.